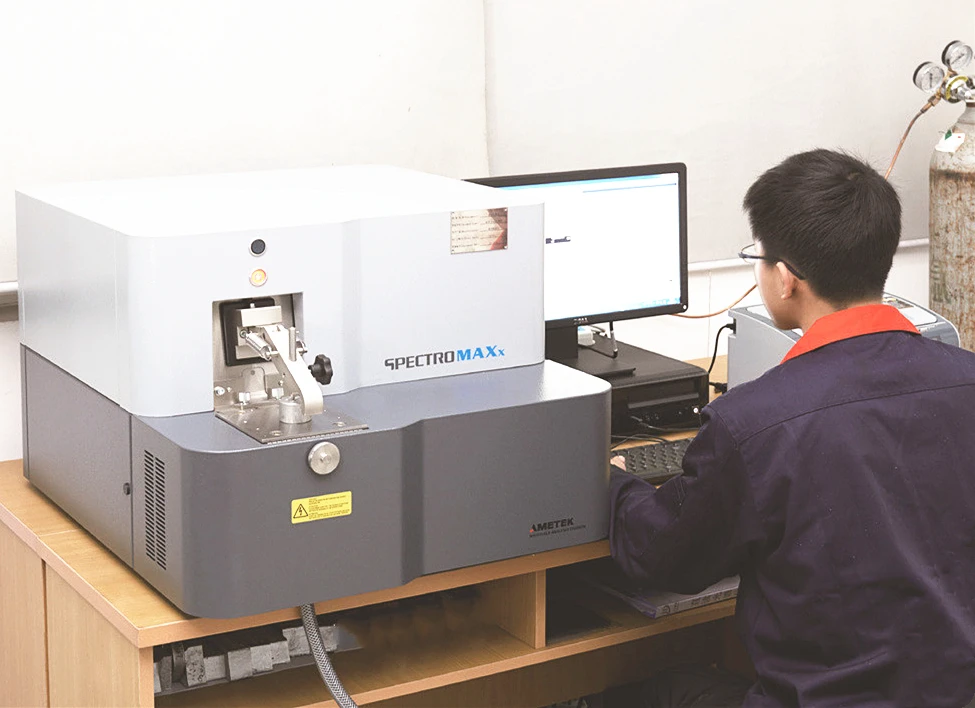

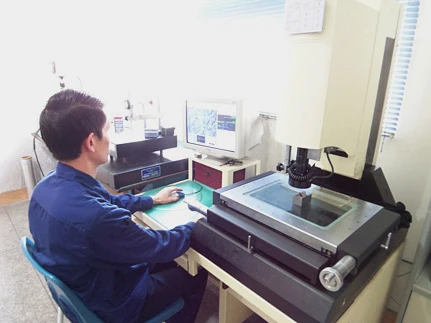

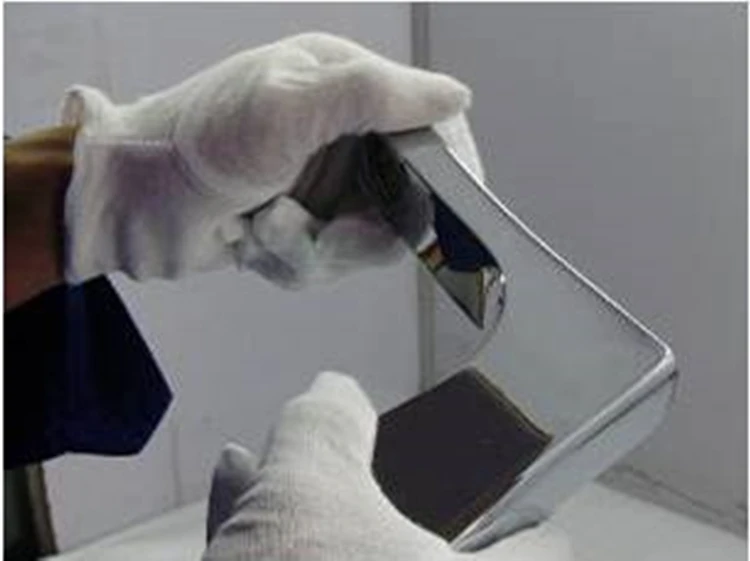

Seven-layer process surface

Up to seven layers of plating process

Quality and manufacturing process can be seen with the naked eye

|

Product Name

|

Kitchen faucet

|

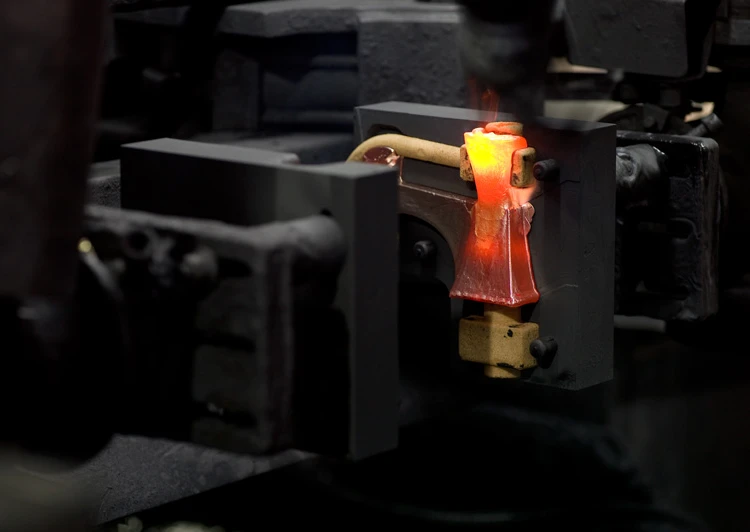

Material

|

Brass

|

|

Brand name

|

SINERMEI

|

Flow rate

|

20L/mins

|

|

Application

|

House

|

Surface Finishing & Treatment

|

Chrome

|

|

OEM&ODM

|

Accept

|

Modes of packing

|

12pcs Packed in 1 cartons

|